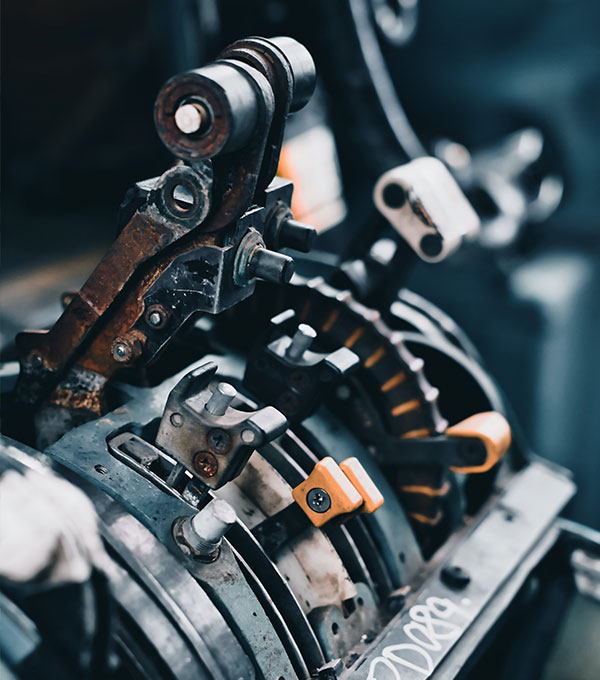

Mechanical engineering

Hypertec Solution develops, with decades of experience, mechanical design, mechanical engineering, and mechatronics with high technological content.

In fact, to interface with every production company, we have the most widespread mechanical design CADs. Our designers also have a very high-quality level in every mechanical design work, thanks to the experience acquired during numerous collaborations with the best European engineering companies.

In any case, our know-how allows us to develop projects that are always at the forefront in the use of materials, construction technologies, and design techniques.

Our services

We deal with mechanical design and full development of new products. From the project to the completed prototypes with the possibility, for example, managing a pre-series. Below is a brief overview of the services offered:

- Criticality analysis

- Definition of the intervention sectors

- Redesign

- Prototype construction

- Experimental verification

General information on planning

The design consists of defining the layout, shapes, and information necessary to make the product. The designer, in this stage, can use his experience and his intuitions to allow the realization of the idea. We can divide this phase into four parts: “Preliminary designing”, “Detailed designing”, “Verifying phase,” and “Issue”.

Preliminary designing

In this phase, solution schemes are developed that meet the specifications already frozen in the previous step. It is always better, as a precaution, to carry out a verification of what exists similar on the market – or that has already been planned -, to being able to find a model that allows to reducing time and costs. It often becomes necessary to produce more general schemes to obtain as much information as possible on the advantages and disadvantages of the possible solutions. At this stage, if the timing consent to it, it’s helpful to evaluate the most significant number of viable routes. Even those that at first glance may seem disadvantageous. The phase finally ends, with the choice of the definitive scheme, the one capable of offering the best compromise with the specifications. This scheme allows us to analyze functions, resistance, spatial compatibility, financial feasibility, and safety.

Detailed designing

On the other hand, the second is when the various construction or commercial mechanical components are defined in detail. Until you have all the information you need to develop the product, at this stage, the design and the structural calculation go hand in hand. All the data necessary to build the piece are expressed in the technical drawings, called “construction tables,” and made according to exact standards (UNI, ISO, DIN) in such a way as to make them universally understood.

All the pieces are coded to facilitate the work management and shown in a list called “bill of materials.” Here is all the information that characterizes the object, such as material, denomination, supplier, quantity, group to which it belongs, and relative note. The code that has been assigned to the piece compares to the comparative table, and sometimes it is also reported on the piece itself so that all information can be instantly available.

Verifying phase

It is necessary to carefully check all the documentation drawn up. And therefore, it is essential to summarize exhaustive geometric definitions, interfaces on the various components compatible with each other, dimensional and geometric tolerances, graphics of the drawings, purpose of roughness, coding, manufacturing and testing notes, heat and surface treatments. The time required for this operation may seem almost superfluous: however, we consider that the next phase is the construction phase. And that therefore a tiny design error could lead to a significant waste of time and resources later. In addition, good design work also minimizes procurement and assembly problems.

Publishing

The design phase ends, in fact, with this phase. That is the delivery of the technical documentation to the various suppliers with whom the times and costs for realizing the products were already established. And, of course, with the order of any commercial components for which an estimate was already requested. Well-organized storage of project files and drawings will save us time during development.

Our strenghts

Innovation

The transversal potential of Hypertec Solution allows to carry out cutting-edge projects, the aspects concerning both single components and complete systems, and customized design techniques satisfying the customer’s needs.

Passion

Hypertec Solution is a set of shared values, new horizons, and boundaries to be overcome thanks to the people who, with pride and passion, realize these ideals every day. Avant-garde, professionalism, and skills: all characteristics that allow us to establish working relationships in transparency and mutual trust.

Engineering design

Hypertec Solution offers the most potent and advanced mechanical engineering tools, professional design and advanced calculation software, automation engineering, and simulation software, which allow you to obtain evidence of the results even before machine testing.

Excellence

The results of Hypertec Solution are always excellent. Our distinctive character is the ability to create dynamic workgroups, characterized by engineers with complementary skills, suitable to meet the needs of those who turn to us to obtain specific solutions