Test benches development

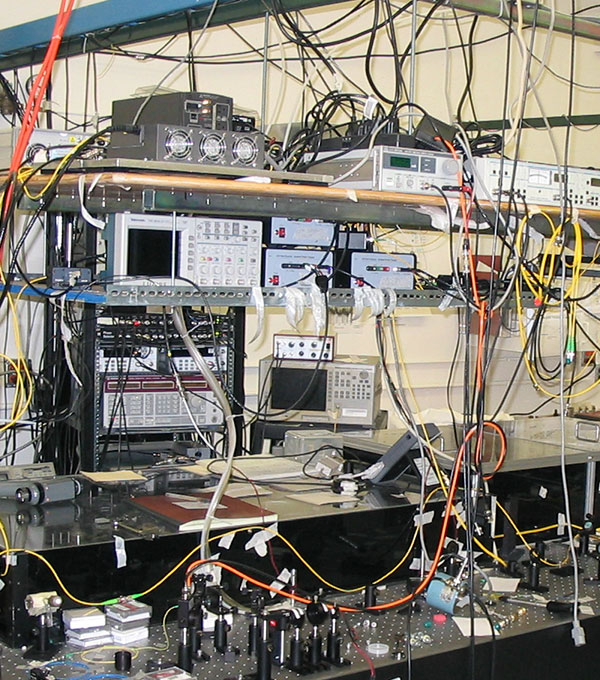

Hypertec Solution develops and manufactures static and dynamic test benches to carry out accelerated checks of the functionality – over time – of mechanical systems. As a component of the development process, test benches are essential to highlight the criticalities of a prototype of the system and correct them before the start of production. We believe verification tests are crucial to ensure product quality and safety, especially for mission-critical components.

Similarly, Hypertec Solution counts on a high level of experience in data acquisition. In summary, we use a scientific approach that combines calculation and simulation theories with experimental verification in the field to obtain effective feedback on the behavior of mechanical systems.

Hypertec Solution also provides an analysis of the reliability of a mechanical system. It can, of course, range from the study of the breakage of a piece to the CAD optimized solution and validated by experimental analyzes in the laboratory or the field. We have extensive experience in Failure Analysis and high theoretical knowledge of design, calculation, and simulation, which is finally concrete in testing and experimental validation.

Types of test benches

STATIC TEST BENCH

Design of static test benches for the validation of a single component or a group.

- Activities carried out

- Product analysis and test definition.

- Analysis and definition of the kinematic systems necessary to generate the test loads.

CAD design, kinematic and structural calculations, choice of the most appropriate commercial and technologies for constructing the test bench.

Data acquisition during the test: all the physical magnifications of interest can be monitored and acquired for subsequent processing, even with dedicated instrumentation of the component under test.

Support in the commissioning of the test bench and the execution of tests.

- Analysis of the results obtained and characterization of the product after the execution of the tests.

PROCESS TEST BENCH

By process test benches, we mean those test benches that have to test special movements of automatic machines or industrial plants. We, therefore, deal with the design of automatic test benches to define the best processing technology or for the validation of a group (automated systems, study of the laws of motion, and practical calculation of the cycle time).

Activities carried out

- Analysis of the product and the required operations.

- Creation of the layout and functional diagram of the test bench.

- Construction design, kinematic and structural calculations, choice of the most suitable commercial and technologies for constructing the test bench.

We draft the technical file and preparing the documentation required by the Machinery Directive relating to the test bench’s assembly, use, and maintenance.

Execution of experimental tests.

Analysis of the results obtained and characterization of the product after the tests performed with the test bench.

FATIGUE / DURATION TEST BENCH

Design of automatic test benches for fatigue/wear characterization of critical mechanical or commercial parts. With the possibility of carrying out calculations to define the necessary loads and how to apply them and perform accelerated tests.

Activities carried out

- Analysis of the product and the required operations.

- Creation of the layout and functional diagram of the test bench.

- Executive design of the test bench.

- Definition of the accelerated test cycle under controlled conditions.

- Redaction of any test control sheets to monitor its progress.

- Implementation in the test bench of automatic control and acquisition systems with data download on remote PC allows real-time control of the test performance and the measured magnitudes without stopping the test and disassembly and the storage archiving of the same.

- Execution of experimental tests.

- Analysis of the results obtained and possible optimization of the product following the tests performed.

Skills and development environments

- PLC – Safety – Motion control

- Siemens Tia Portal S7-1500-1500T

- Rockwell Automation Studio5000

- Schneider-electric PDM-PD3 Epas4-SoMM-MSE system integrator (*)

- B&R Automation Studio (*) Beckhoff TwinCAT 3 system integrator

PLC

- Siemens S7-300

- Siemens Tia Portal S7-1200

HMI

- Siemens Wincc

- Rockwell Automation FactoryTalk

- B&R VC4 and MappView

ROBOTICS

- Schneider-electric – Robotic NG

- Robots integrated into machines and/or automated systems

- FANUC

- KUKA

- Kawasaki

- ABB

Our strenghts

Innovation

The transversal potential of Hypertec Solution allows to carry out cutting-edge projects, the aspects concerning both single components and complete systems, and customized design techniques satisfying the customer’s needs.

Passion

Hypertec Solution is a set of shared values, new horizons, and boundaries to be overcome thanks to the people who, with pride and passion, realize these ideals every day. Avant-garde, professionalism, and skills: all characteristics that allow us to establish working relationships in transparency and mutual trust.

Engineering design

Hypertec Solution offers the most potent and advanced mechanical engineering tools, professional design and advanced calculation software, automation engineering, and simulation software, which allow you to obtain evidence of the results even before machine testing.

Excellence

The results of Hypertec Solution are always excellent. Our distinctive character is the ability to create dynamic workgroups, characterized by engineers with complementary skills, suitable to meet the needs of those who turn to us to obtain specific solutions